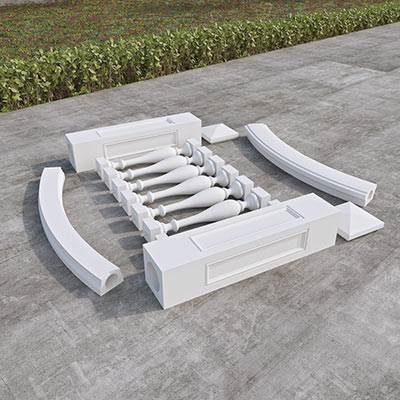

FACADE PROFILES

INSTALLATION

-

Mark upper cover of the cornice,

50 mm away from the edge.

-

Strike a line with a chalkline

between the marks on the cornice shelf.

-

Cut the cornice cover as marked.

-

Attach the item to the mounting spot.

Firmly press the item to the wall and the ceiling,

and mark the wall along the bottom edge

of the product.

-

Strike a line with a chalkline connecting the marks.

-

Using an adjustable square,

measure the angle of the building.

-

Using a mitre saw adjusted to the appropriate

angle, make a cut into the item.

-

Finish the cut with a hand saw.

-

Cut the next item.

-

Check that the item‘s pattern and profile match.

-

Evenly spread Evroplast Multipurpose Adhesive

along the entire item. The layer

of adhesive should be 3–5 mm thick.

-

Place the item to the mounting spot, according

to the markings on the wall. Press the item

along the entire length hard enough

to make the adhesive exude from the joint.

-

Use a perforator to make holes

for impact anchors spaced at ~600 mm.

-

Fix the item in place with impact anchors.

-

Use a screw gun to drive the impact

anchors‘ heads into the item – 2 mm deep.

-

With the screw gun and a self-tapping screw pull

the upper part of the item and sink

the screw‘s top 2 mm into it.

-

Immediately after putting in the self-tapping screws

remove excess adhesive with a palette knife.

-

If necessary, rub the spots where the item touches

the surface with an acetone-soaked cloth.

-

Use a moistened cloth to clean the butt ends

of the adjoining items from dust and other dirt.

-

Put the Evroplast Adhesive for bonding joints

on the free end of an already-mounted item.

-

Spread the Evroplast Multipurpose Adhesive

along the entire next item to be mounted

(on the surface to be attached).

The layer of adhesive should be 3–5 mm thick.

-

Attach the item to the mounting spot.

Press along the entire length hard enough

to make adhesive exude from the joint.

Sliding the item along the wall,

press it against the neighbouring item

so that adhesive exudes from the joint.

-

Attach the joint with self-tapping screws.

-

Continue assembly by repeating steps 10–15.

-

Remove excess adhesive with a palette knife i

mmediately after gluing.

-

Rub the joint with an acetone-soaked cloth.

-

Continue to the next item.

-

In places where an item abuts the surface

and no adhesive has exuded from the joint,

fill the gaps with more adhesive.

-

Use acetone and cloth to remove extra adhesive.

-

Wait 3 hours and apply soft sand paper

to the joints for an even surface.

-

Apply putty to the treated spots and over

the heads of screws — use automotive putty.

-

After the putty has dried, polish the treated

spots and filled screw holes with soft sand paper.

If necessary, repeat step 28.

-

Consult paint manufacturer instructions

and paint the mounted items starting

from the corner of the building.

-

View:

- 1 - 8

- 9 - 16

- 17 - 24

- 25 - 30

- All